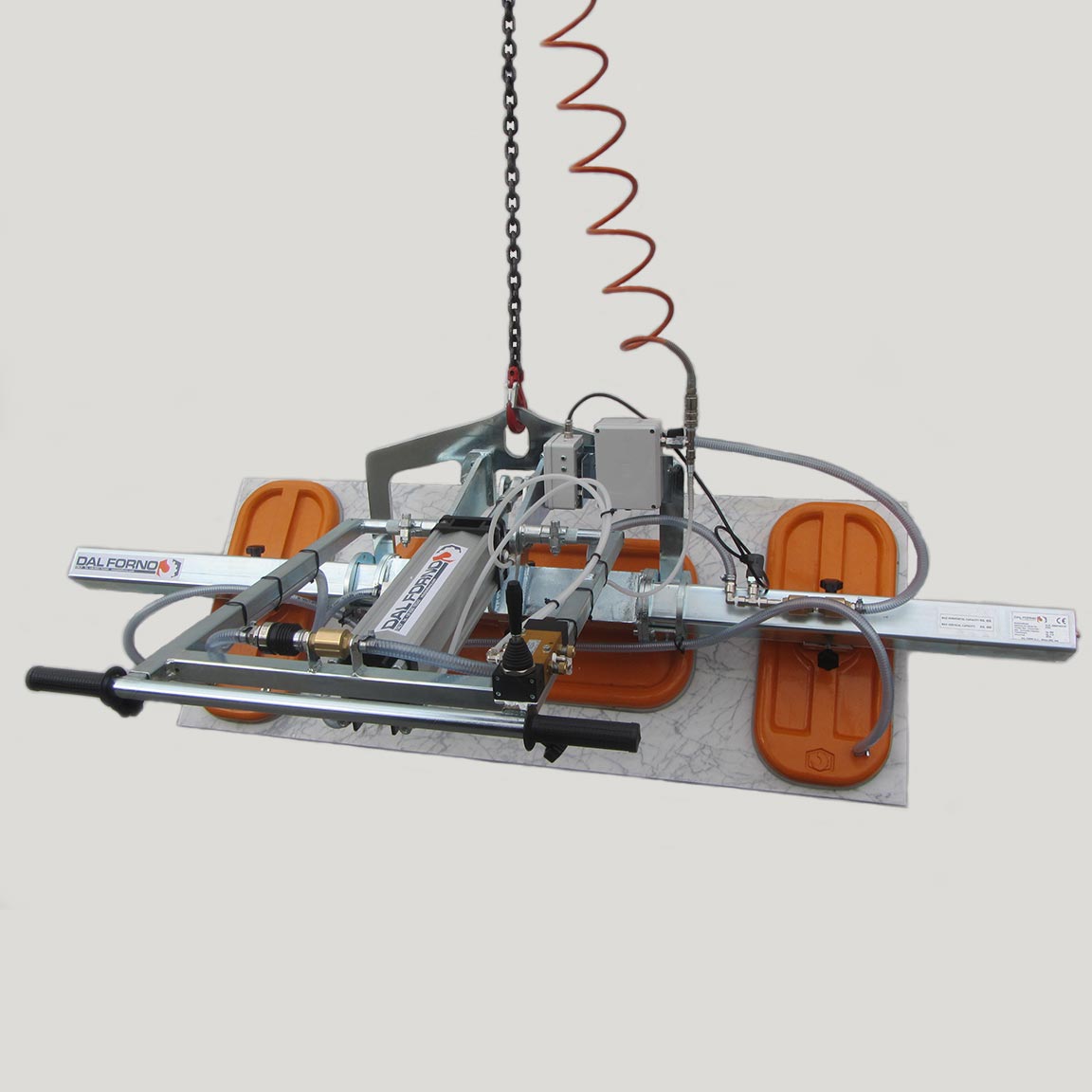

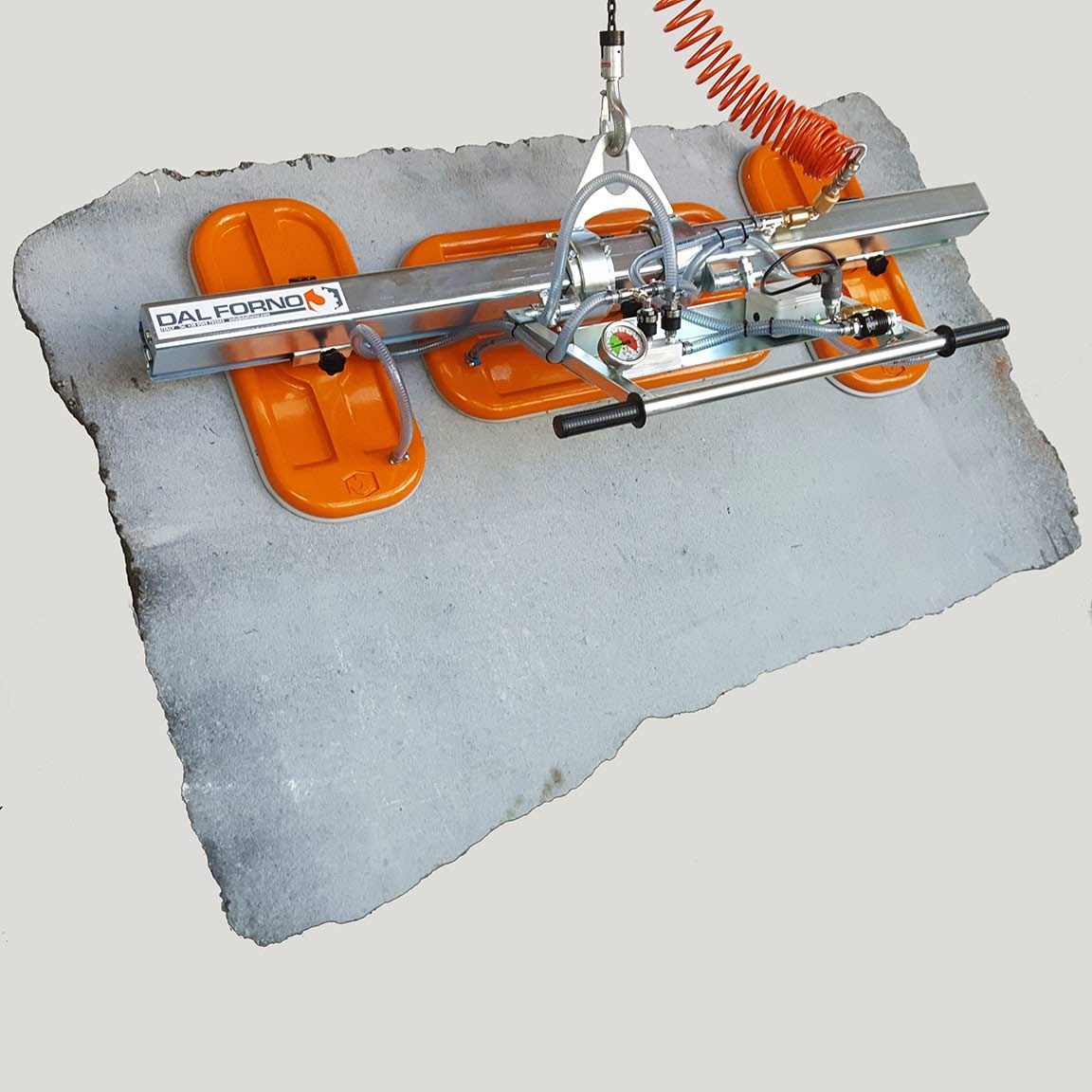

Stone vacuum lifter | three pads | compact pneumatic tilting

VL SERIES

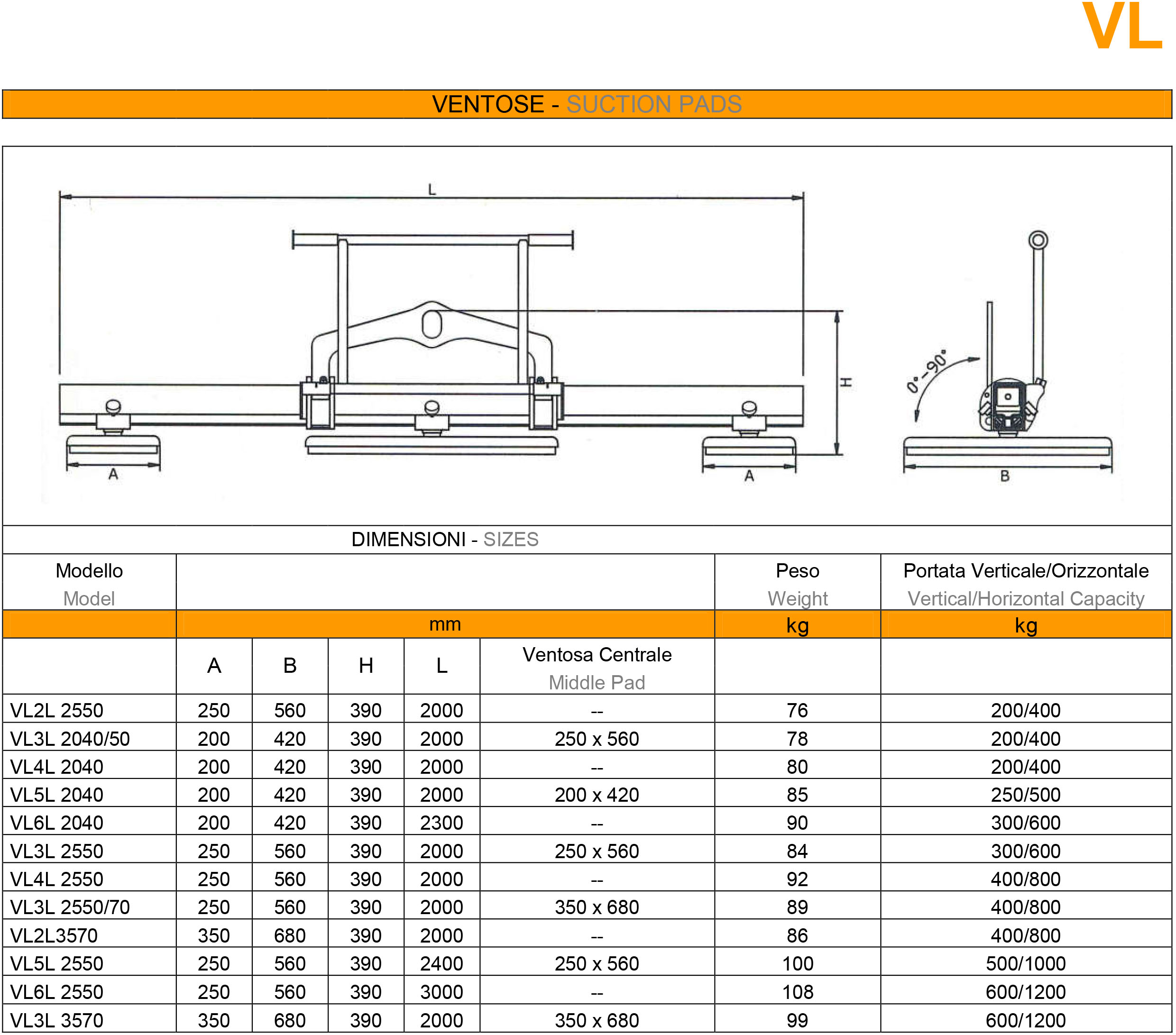

Capacity: 400 to 1200 kg

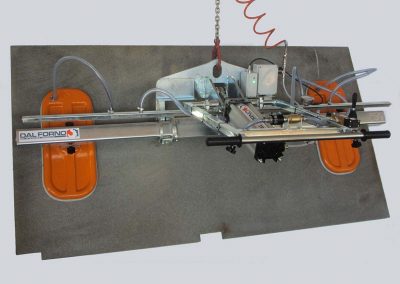

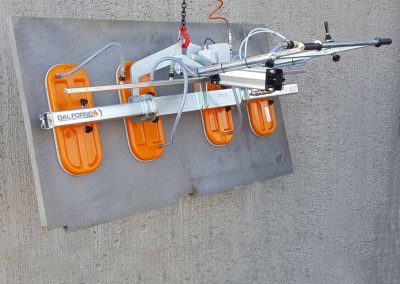

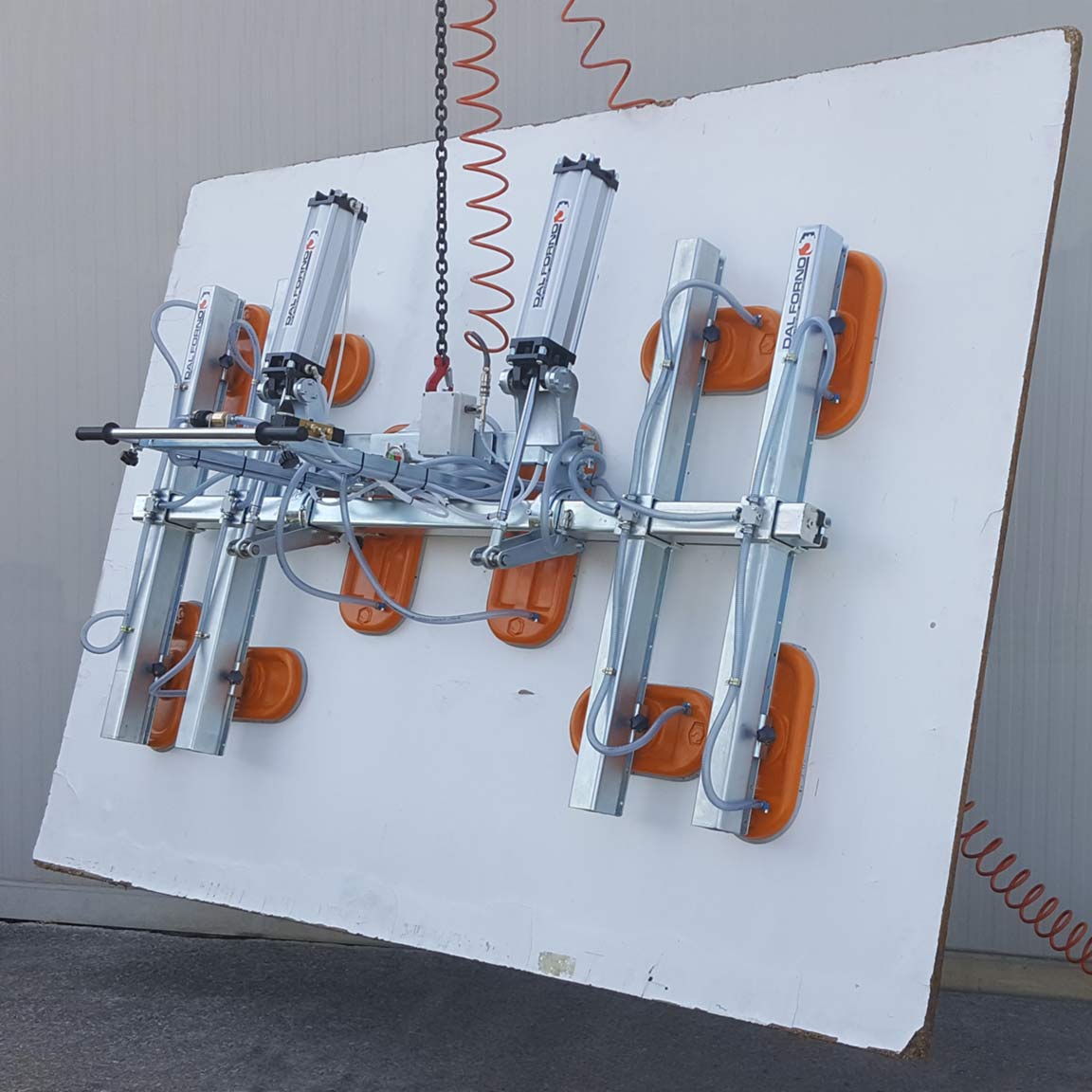

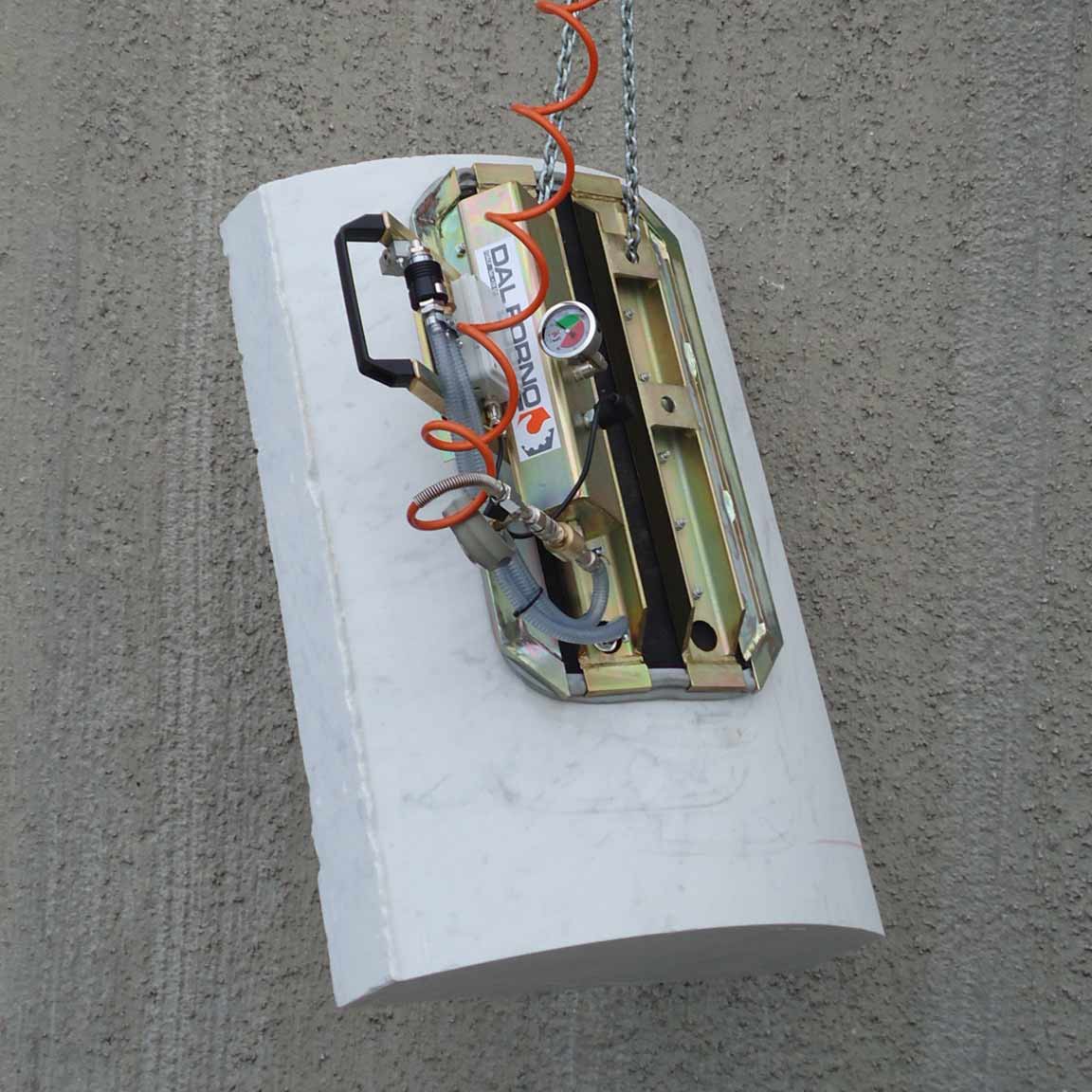

Stone vacuum lifter (marble and granite vacuum lifter) engineered to excel in the handling of solid, non-porous materials with flat surfaces.

These materials encompass a wide range, including cut-to-size panels, tiles, strips, stairs, small slabs, metal plates, and window glasses.

What sets this lifter an all our vacuum lifters apart, is their advanced technology, compact design, and robust construction. They are meticulously crafted to meet the highest industry standards, ensuring dependable performance and durability even under the most demanding conditions.

Designed for fast and straightforward material handling. Compact and sturdy construction, ideal for continuous and heavy-duty use.

Equipped with a vacuum reservoir, provide an added layer of safety, complemented by built-in safety devices featuring both acoustic and luminous alarm systems. This ensures that your material handling processes are not only efficient but also secure.

A significant innovation lies in our distinctive rubber sealing, which is flexible, robust, and exceptionally long-lasting. This unique sealing technology allows for the secure grip of materials with various surface finishes, be it raw, polished, honed, flamed, bush-hammered, sandblasted, and more.

Our stone vacuum lifters represent a significant leap forward in material handling technology. Their combination of advanced features, compactness, and robustness ensures that you have a reliable partner for your material handling needs. Whether for stone, marble, or other materials, these vacuum lifters are engineered to deliver exceptional performance and longevity, making them a valuable addition to your lifting equipment arsenal.

- manufactured with light alloy materials and galvanized steel, aluminum casting pad – long-life and rustproof;

- fast and easy replacement of the rubber sealing ring;

- can be tilted 0° to 90°, to lift and lay down materials both horizontally that vertically (upright);

- pivoting axis close to the pad to facilitate the vertical positioning;

- adjustable inclination of the maneuvering handle;

- detactable and rechargeable vacuum leakage alarm with buzzer and warning lights activated by a vacuum switch, apart battery charger;

- one-direction valves to allow vacuum keeping also in case of pipe cuts/vacuum loss;

- ON/OFF sliding valve with locking device against accidental releasing;

- in compliance with the CE Machine Directive to conform the EU standards for CE marking.

The vacuum is generated by an electric pump or by means of a compressed air vacuum generator (Venturi pipe). The unit usually consists of: electric vacuum pump + connecting pipe + vacuum suction pad. The vacuum pump is to be placed nearby the working place. For special application can be supplied pumps with single-phase, DC electric motors (to be installed on fork lift and hydraulic crane), internal combustion ones.

Click here to download the technical data.

You can also download the implementing Instructions.

Technical data

Special designed units can be tailored to meet customer’s requirements.

See all the range of our vacuum lifters.