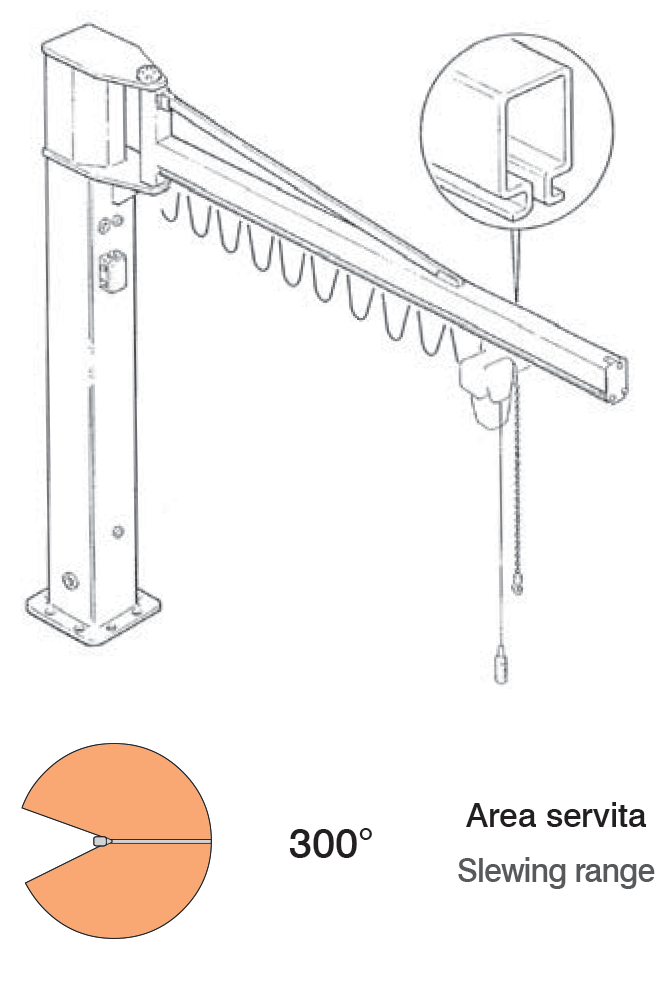

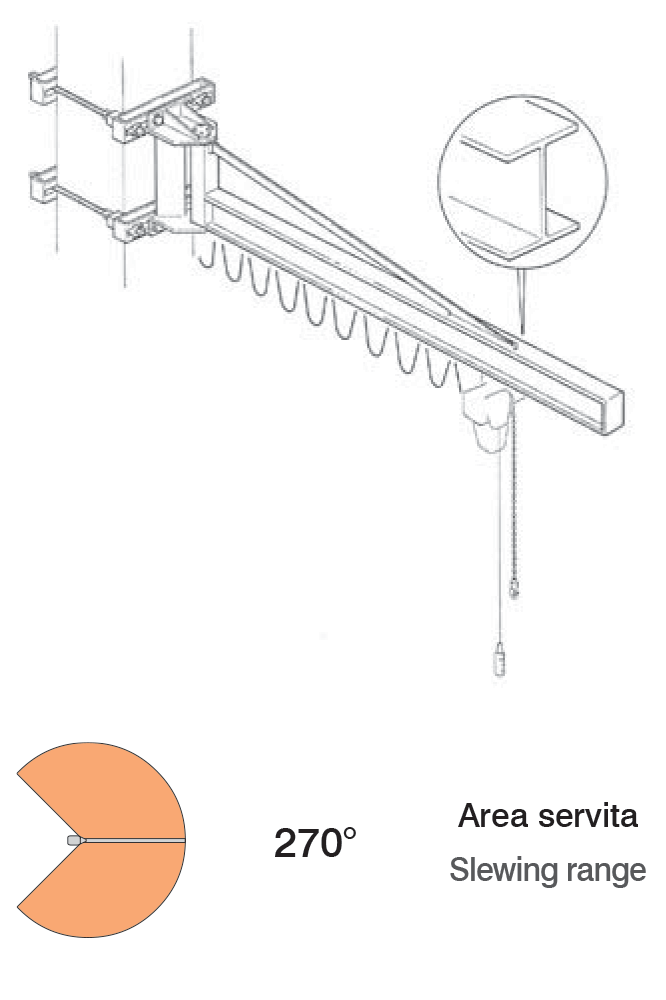

Channel profiled jib crane

Equipped with

For more information

CONTACT US

Download

Click here to download the technical data.

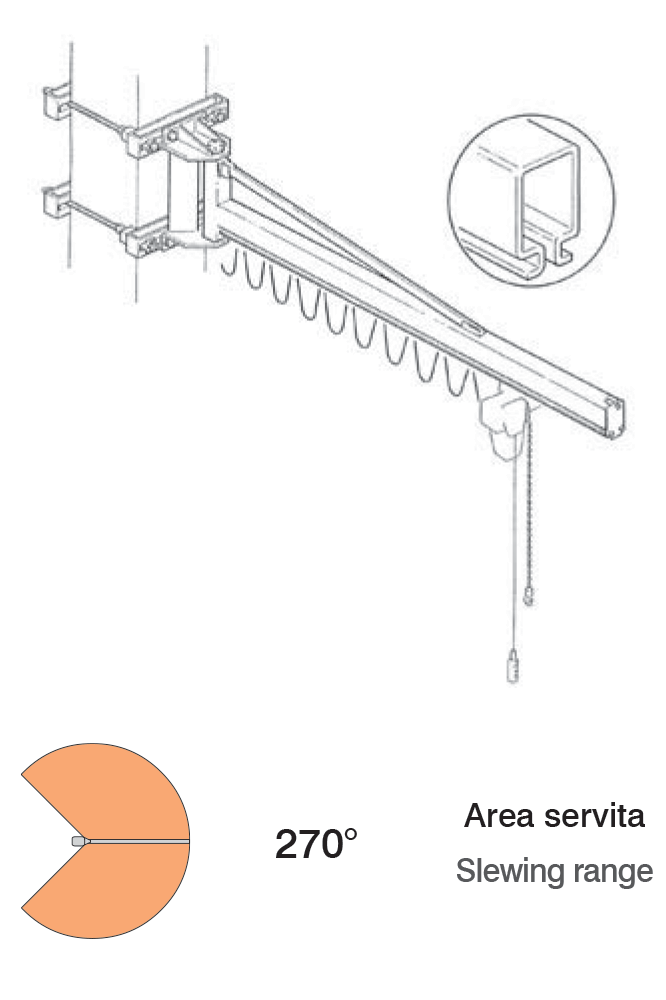

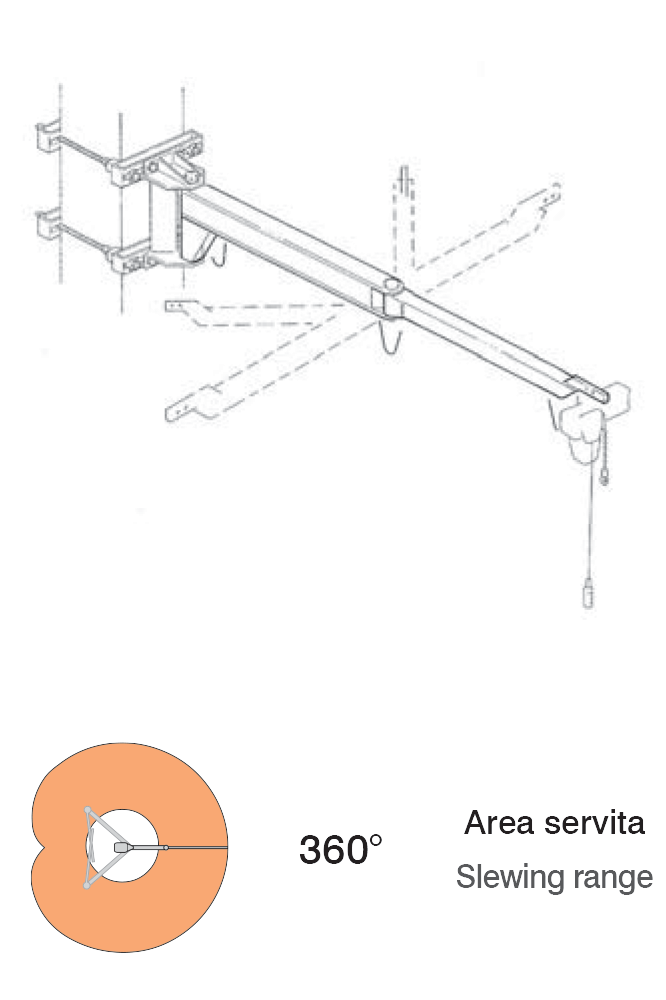

Overbraced jib crane

Equipped with

For more information

CONTACT US

Download

Click here to download the technical data.

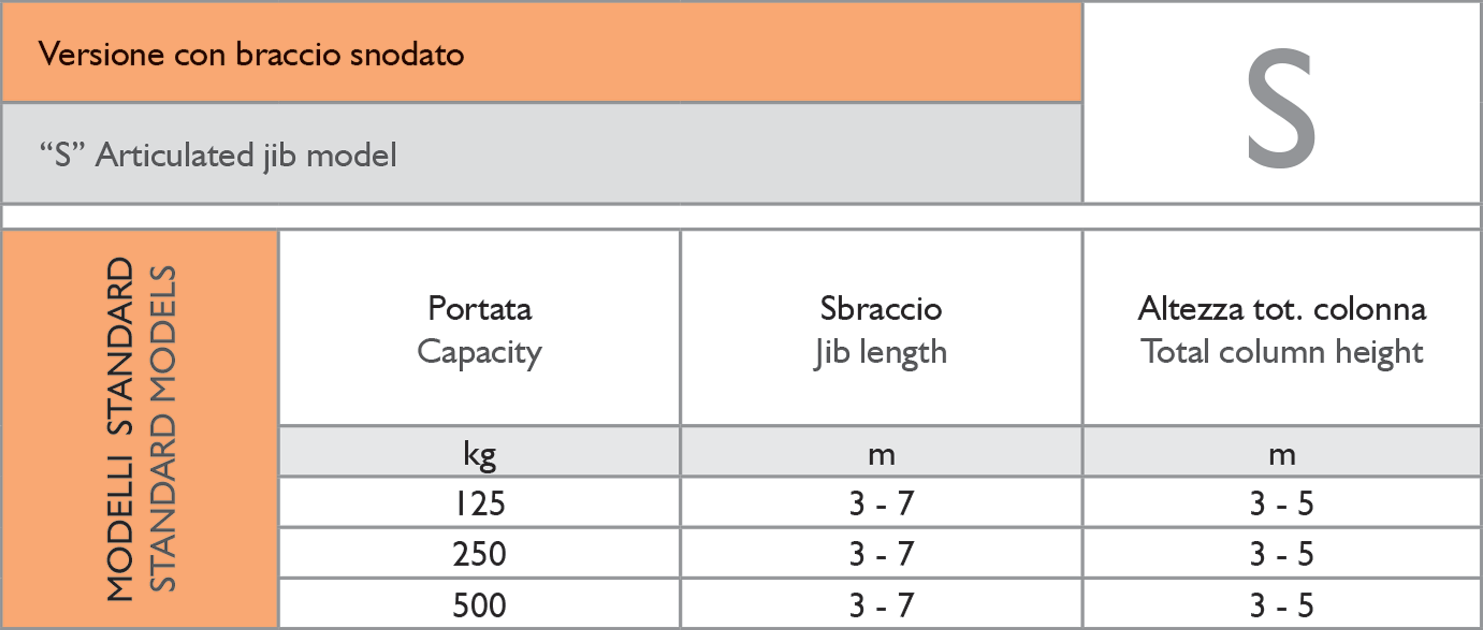

Articulated jib crane

“S” model | double hinged arm crane

Capacity 125 to 500 kg

Jib length 3 to 7 m

The arm of this model is articulated in two “hinged segments” which allow the handling even if fixed obstacles are present. This model permits the best use of the vertical room available and the clockwise/anticlockwise swing for more than 360°.

Equipped with

For more information

CONTACT US

Download

Click here to download the technical data.

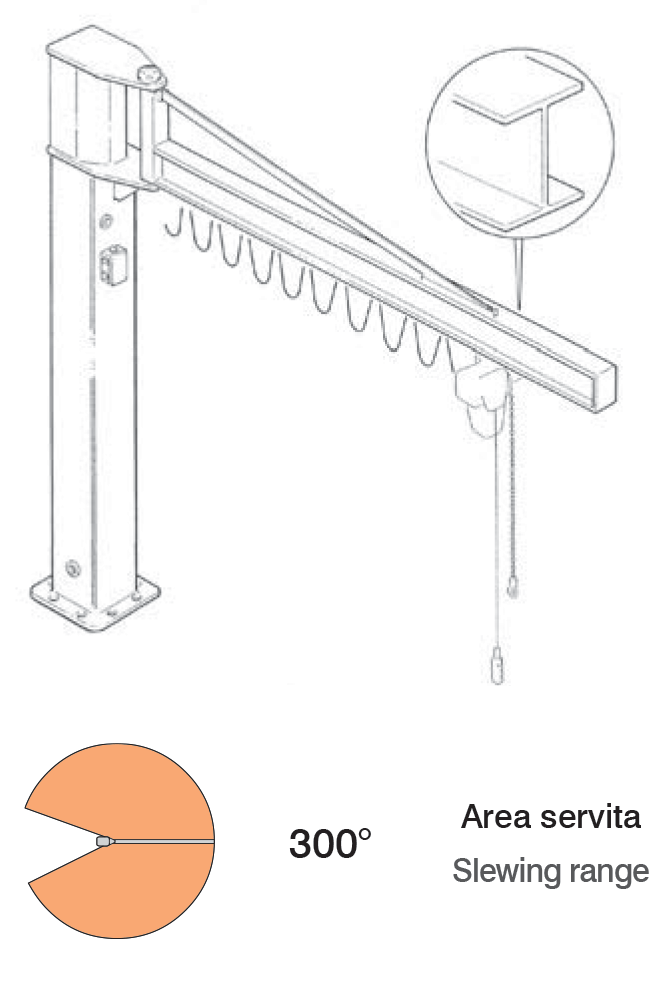

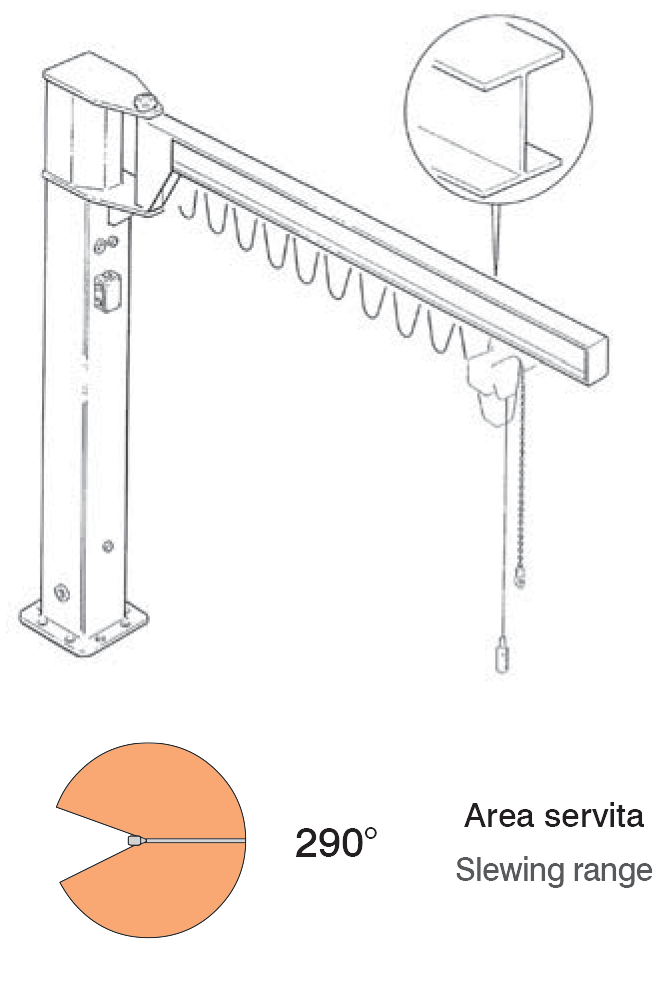

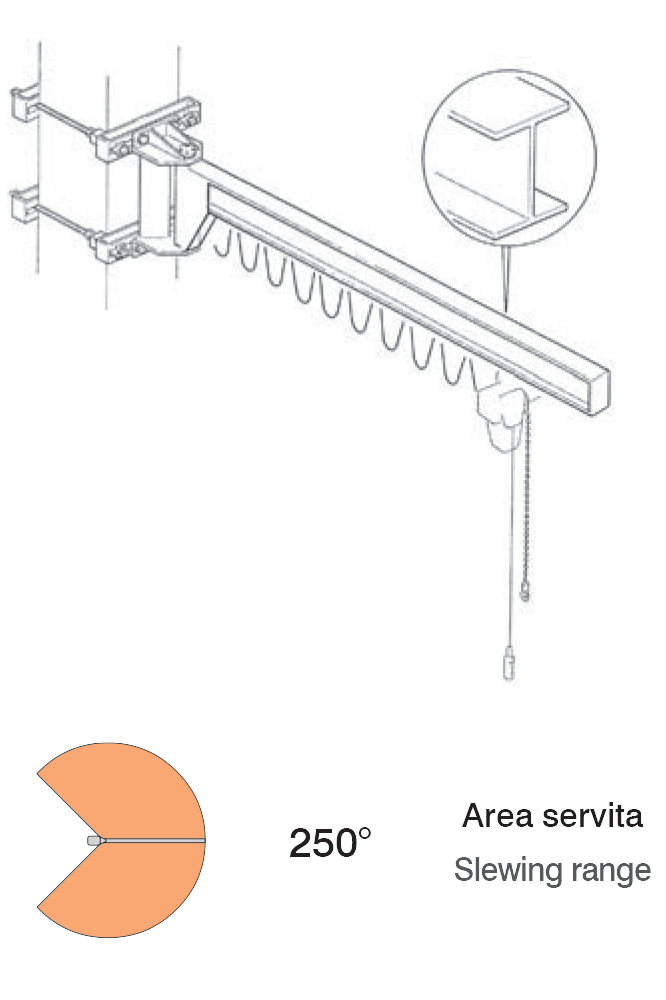

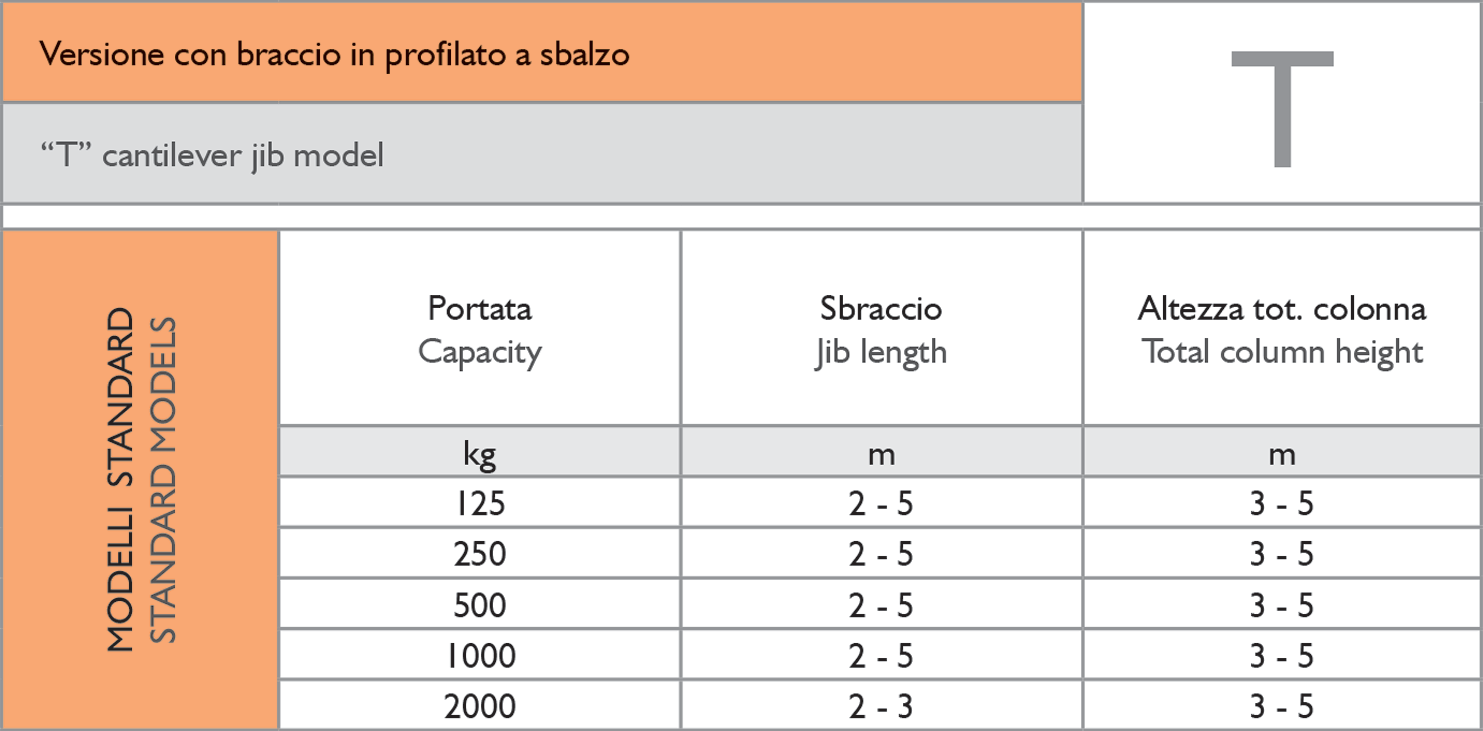

Cantilever jib crane

Equipped with

For more information

CONTACT US

Download

Click here to download the technical data.

Make the most of tight spaces

with slewing cranes

Optimization of material flow in your business processes

Jib cranes are excellent material handling solutions, especially in environments where space and footprint are limited. However, to realize their full potential, it is important to select the right model, position it correctly, and follow safety regulations and protocols.

Key factors to consider

when selecting the optimal jib crane:

- Asset the range

- Evaluate reach

- Select the type of jib crane

- Choosing the type of drive

- Select the hoist

- Select the vacuum lifter

- Correct positioning of the slewing crane

- Practical ways to use it efficiently and safely

Our guide pages (click on the buttons below) can help you fine-tune your project to optimize the handling processes in your plant and company.

By following these guidelines, you will be able to evaluate the main parameters to be taken into account and then, thanks to our advice, make the final choice of cranes and vacuum lifts that best suit your needs and the requirements of your production line.

We can accompany you on a multifaceted journey and provide you with the information you need:

- Choose the ideal slewing crane: together we will analyze capacity, reach, type of erection and technical characteristics to help you find the perfect solution for your needs.

- Positioning the jib correctly: you will discover the criteria to consider for a safe and efficient installation that maximizes the performance of the crane and the productivity of your work.

- Operate the jib crane safely: Learn about current safety regulations and best practices for risk-free operation that protects operators and equipment.

Make slewing cranes valuable allies

to optimize material handling

and boost your business.

Discover the benefits of jib cranes:

- Efficiency in confined spaces: make the most of every square meter with lifting and handling solutions designed for compact environments.

- Versatility: discover the wide range of applications for slewing cranes, from industrial sectors to workshops, warehouses and construction sites, optimally combined with our vacuum lifts.

- High level of safety: follow our advice for safe and compliant use to ensure the safety of you and your employees.

Start now to optimize your production processes

with DAL FORNO slewing cranes and suction cup lifts!

Take advantage of our qualified • consulting services •